About Us

Builders of Fine Hardwood Furniture

In 1992 Barkman Products built primarily wooden toys and household accessories, but soon moved into the manufacture of cabinet doors and contract furniture, such as retail fixtures. Additional production space was needed, and in 2008 Barkman Products owner and president Albert Barkman and his wife Fannie purchased a newer facility with space sufficient to allow for rapid growth and expansion of the product line.

This expansion allowed Barkman Products not only to dramatically grow the door and contract parts of the business, but also to introduce an extensive line of fine hardwood furniture for the home. Now, Barkman Furniture hosts an abundant selection of superior quality hardwood dining, office and bedroom furniture, as well as many unique occasional tables, accent pieces and accessories, all available to be custom-built in a variety of unique finishes and delivered rapidly to the customer.

The Journey from Forest to Home

The crafting of fine furniture is, indeed, a journey. Starting with intentional designs created with the end user in mind, and resulting in heirloom-quality furniture that will last for generations to come, making the trip with Barkman is sure to be worthwhile

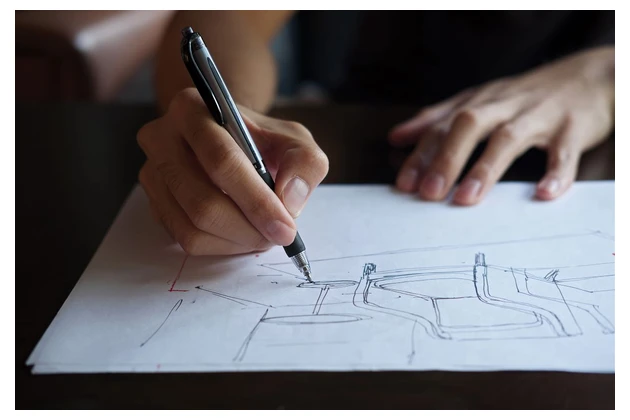

Design

Barkman’s furniture is designed for exceptional comfort and style, taking into account the functionality of the piece. Our in-house team works together to design furniture that is not only aesthetically pleasing, but enjoyable to use and built to last for generations.

Inception & Preparation

Hardwood logs used in the construction of Barkman’s furniture are sourced exclusively from sustainable Midwest forests. The logs are processed into lumber which is graded, sorted, and dried to ensure proper seasoning. Once the boards are adequately seasoned, they are used to build panel and frame components at incredibly close tolerances with state-of-the art equipment.

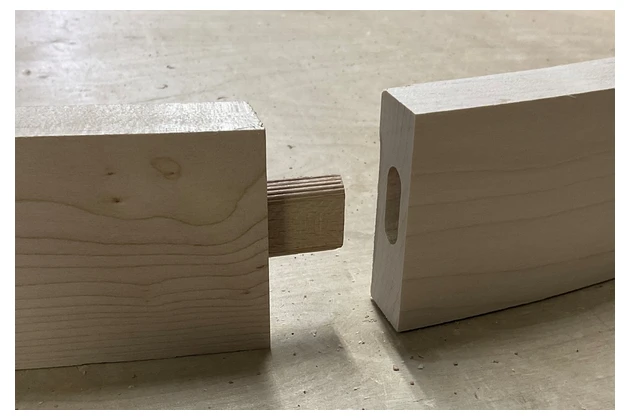

Production

The construction of a piece of furniture begins with framing, using time-honored techniques for joinery such as dovetailing, tongue-and-groove, box joints, and mortise-and-tenon. These methods have been used for centuries to build furniture that stands the test of time and bears the unique signature of the craftsperson who built it.

Perfection

Once the piece is assembled, hours of planing, filling small knots, and hand-sanding ensure that it is perfectly conditioned to properly absorb the finish that was chosen for it. The process of applying the finish utilizes a combination of automated spray application, hand-wiping, and hand-sanding techniques. The result is an impeccably smooth finish that provides protection and enhances the natural beauty of the wood, which only improves with the patina that time creates.

Delivery

Barkman employs a variety of dependable delivery services to transport each piece securely to the retailer who purchased it. White glove delivery can also be arranged to bring the piece directly to the consumer’s home, where it will be installed by professionals. Each piece of furniture is blanket-wrapped and carefully loaded to ensure that it arrives safely to its destination.